![]() SOYA Steel Ball Factory The leading steel balls manufacturer & supplier from China.

SOYA Steel Ball Factory The leading steel balls manufacturer & supplier from China.

![]()

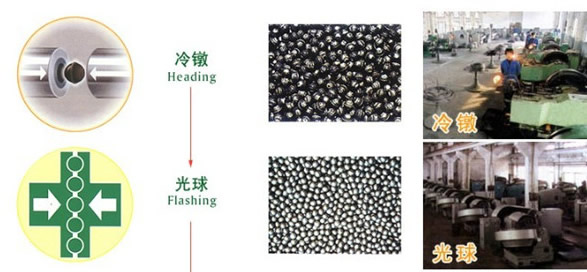

How is the steel balls produced?

The steel balls production process is divided into several processes,

they are wire drawing, cold heading, coarse grinding, heat treatment,

soft grinding, hard grinding, lapping, superfinishing, polishing, etc.

Wire Drawing: Stretch the raw material steel wire to the required diameter size;

Cold Heading: Forging the steel wire into irregular spheres;

Coarse Grinding: Grind off the burrs and irregular surfaces of the steel balls,

make the steel balls more circular;

Soft Grinding: On the basis of roundness, make the size of the steel balls more precise;

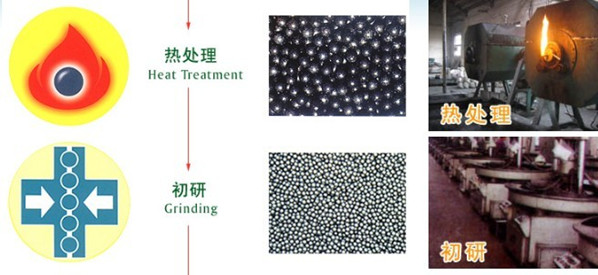

Heat Treatment: By carburizing treatment, increase the hardness of the steel balls;

Hard Grinding: Further increase the precision of the steel balls,

make the diameter tolerance more in line with the requirements;

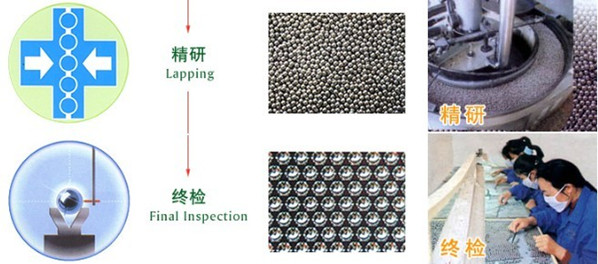

Superfinishing: More precise processing and grinding, spending more time

to make the size of the steel balls more precise;

Polishing: Make the surface of the steel balls to be more brighter, cleaner, and shinier.

Test: Test the steel balls one by one, every steel ball will be detected,

ensure that each steel ball meets the requirements.

The steel balls with different grade have different precision requirements.

If the precision requirement is low, the production process and time will be reduced.

If high precision is required, the production process and time will increase.

Different materials will have different production processes.

SOYA Steel Ball Factory can customize production according to customer

requirements, with special sizes, special raw materials, and special grade.

SOYA Steel Ball Factory can provide various production materials and videos.

Welcome to explore and research together, to explore more precise steel balls.

Tell us your balls requirements, the offer will be send you at the first time.

* According to the AISI standard |

|---|